In the world of hotmelt adhesives there are some concepts that we must know before using this type of adhesives. They are basic notions that will help us discover hotmelt adhesives for excellent results. We refer to open time and bonding time, two terms that we explain below.

In recent years, the performance of hotmelt adhesives has improved with precision. At Productos Colcar, S.L., don’t give up our efforts to apply the latest technologies to achieve durable and reliable adhesives that guarantee exceptional results.

However, the guarantee of final bonding may vary depending on factors such as open time and bonding time. Two basic concepts that we should know and that will help us to discover hotmelt adhesives for better results.

Open time

Many times we have wondered how much time can elapse since we apply a hotmelt adhesive on one surface until bonding with the other substrate is made. This is technically known as open time, a term widely used by those who develop our activity in this sector.

Open time is the maximum time that can elapse from the time the adhesive is applied until the bond is made with the other substrate

It is very important that the substrates stick together within the open time so that adhesion is successful. Otherwise, if they adhere later, the adhesive will be too cold and, although it might seem that the parts have been glued correctly, after 24 hours, it is possible that the bond will be deficient. An open time problem is detected because when the adhesive is removed, it only adheres to one of the substrates.

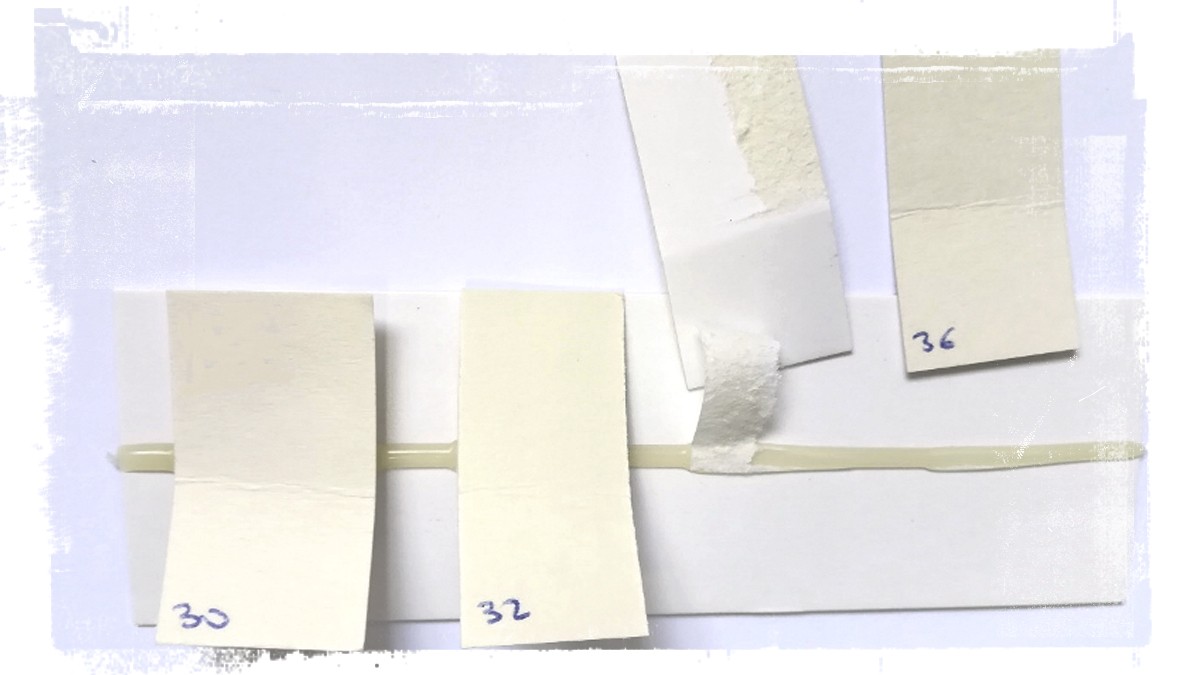

This is an example of open time tests on cardboard. The procedure is as follows: the adhesive is applied to one of the cartons and smaller pieces are glued every 2 seconds. After 24 hours, the pieces are pulled. As you can see, at 36 seconds it takes off without problems and at 34 it already breaks fibers. This indicates that the open time of this adhesive under the conditions used is about 34 seconds. After this time bonding is not correct

To dig deeper into this aspect, it must be taken into account that open time of a certain hotmelt adhesive depends on multiple factors, such as:

- Adhesive application temperature.

- Amount of adhesive used (grams per meter).

- Type of surface on which we are going to apply the adhesive.

- State of the substrate (cold, hot, humid …).

- Environmental conditions (temperature, humidity, etc …).

Thus, an easy way to increase the open time of a given adhesive is to increase the application temperature or by adding more quantity of adhesive. Likewise, to reduce your open time you just have to reduce the application temperature or quantity.

Bonding time

Another issue that assails us when we are ready to use hotmelt adhesives is how long we have to wait for two substrates to be fully bonded. This is what we call the bonding time.

Bonding time is the time that has to pass to obtain a satisfactory bonding

To check if we have respected bonding time of the adhesive , we will try to separate the glued pieces. If the pieces break out or it is impossible to take them off, we will be certain that we have acted properly. On the contrary, if the substrates take off and remain adhesive on both sides, it will mean that bonding time is longer.

When removing off two substrates, if adhesive remains only in one of them there is an open time problem; while if it remains in both there is a problem of bonding time

If you have any questions about these basic concepts, you can contact us through marketing@productoscolcar.com. We will do our best to resolve any issue!