One of the elements that can negatively influence the effectiveness of hot melt adhesives is temperature. In extreme conditions, hot melt adhesives may not provide the same performance. In this post we tell you how you can maintain the effectiveness of hot melt adhesives and fulfill your purposes.

You probably already know that hot melt adhesives provide excellent performance in their various fields of application. However, you should also know that this performance can vary if the glues are applied in disregard of the conditions recommended by the manufacturers. In any case, quality is the parameter that guides us in the pursuit of excellence.

One of the elements that can negatively influence the effectiveness of hotmelt adhesives is temperature. During the change of seasons, it is very common that these solid thermoplastic compounds at room temperature do not provide the same performance. The extreme cold of winter or the oppressive heat of summer are not good allies for the application of these adhesives.

Temperature fluctuations influence the effectiveness of hot melt adhesives

Winter is here and with it the temperatures start to drop. A climatic change, to which hot melt adhesives are no strangers, which could show alterations in their instant adhesion, depending on multiple factors such as the amount of glue applied and the temperatures of the products to be bonded.

To optimise the bonding between substrates, we recommend that you balance the temperature of the equipment whenever you detect sudden alterations in the mercury, taking into account that these glues work at temperatures between 150 and 190 ºC.

Whenever you detect sudden changes in the mercury, we recommend that you balance the temperature of the equipment.

It is important to keep in mind two concepts that influence the effectiveness of the adhesive:

- The bond-forming temperature: this is the minimum temperature below which sufficient wetting of the substrate does not occur.

- The viscosity of the melt: it depends on the temperature, so the higher the temperature, the lower the viscosity of the adhesive. It also influences the spreading of the applied adhesive and the wetting of the surfaces.

Recommendations for use of hot melt adhesives

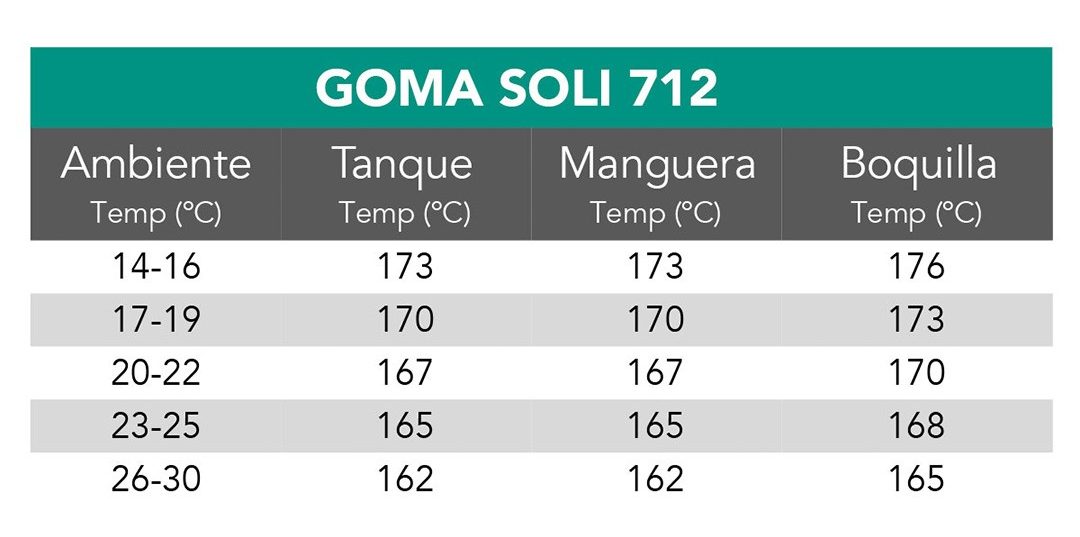

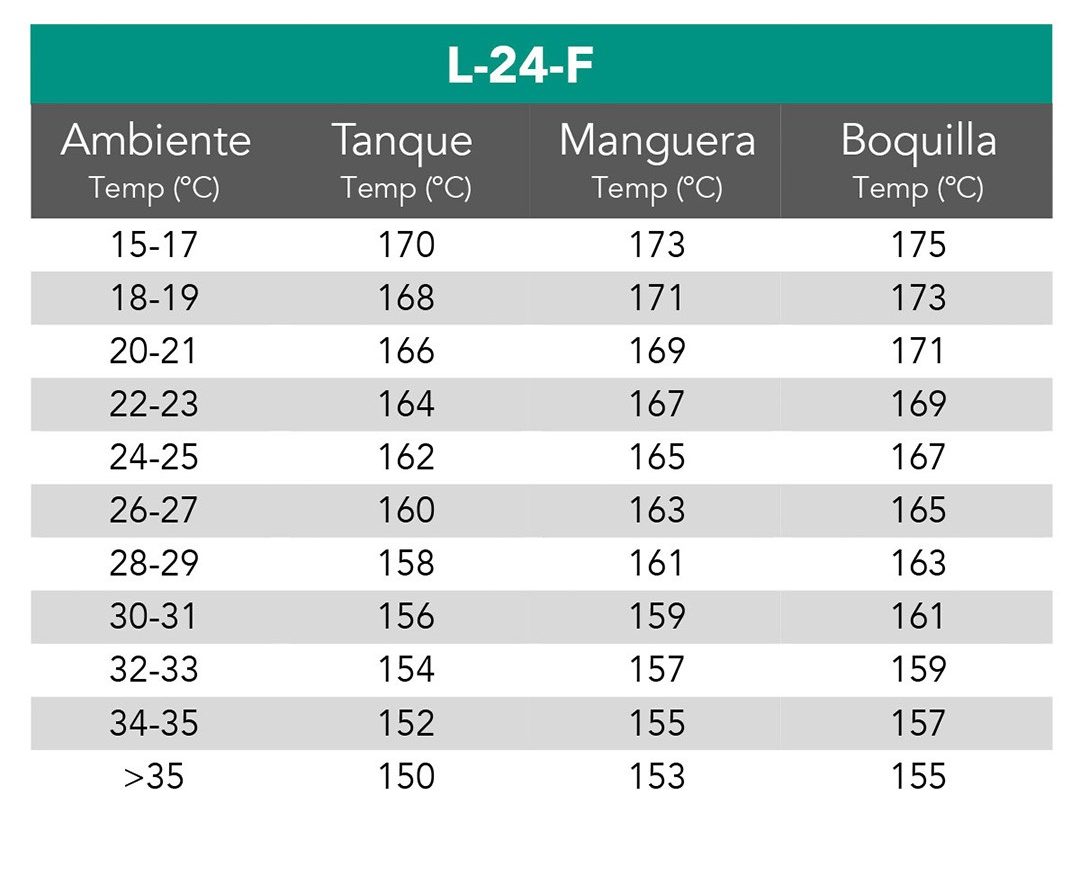

At Productos Colcar we have manuals containing detailed information on the application temperatures of our glues according to the ambient temperature in the factory, thus we intend to provide our customers with the correct use of our hot melt adhesives.

By way of example, the following graphs show the most typical values and are therefore useful for orientation purposes.

As a starting point, we have established the temperature that must be present in each of the parts involved in the application process of a hot melt adhesive (tank, hose and nozzle) calculated based on the ambient temperature of the factory.

As you may have noticed, in winter, in addition to keeping warm, you must regulate the temperature of the machines you use to apply the adhesives which, in case you don’t know, are manufactured using energy from renewable sources!

Finally, remember that the behaviour of the adhesive will also depend on the quantity applied to the substrates to be bonded.

If you need more information about the application temperature of a particular adhesive, you can contact us at marketing@productoscolcar.com.